Effect of chemical treatments on the mechanical and physical performance of corn straw fibers in cement mortar

Abstract

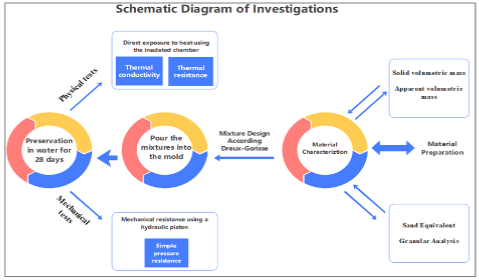

This study investigates the effects of water, acetic acid (CH3COOH), and sodium hydroxide (NaOH) treatments on the physical and mechanical properties of corn straw fibers in cement mortar. The use of natural fibers in cement composites offers a promising approach to reducing reliance on synthetic materials and utilizing agricultural byproducts. Chemical treatments like NaOH and CH3COOH improve fiber-matrix bonding, which is critical for enhancing the mechanical properties of the composites. NaOH treatment resulted in the most significant improvements, with surface roughness increasing by 104.8% and compressive strength reaching 52.8 MPa at 1.5% fiber content after 28 days. CH3COOH treatment boosted early-stage flexural strength, achieving 6.75 MPa at 7 days, but its long-term effect was limited. Water treatment showed minimal impact on fiber performance. These results indicate the potential for NaOH-treated fibers to enhance the strength and durability of cement-based materials.

References

[1]Wen L, Yan C, Shi Y, et al. Mechanical and thermophysical properties of concrete with straw fiber and straw ash. BioResources. 2024; 19(4): 8007–8019.

[2]Ma G, Yan L, Shen W, et al. Effects of water, alkali solution and temperature ageing on water absorption, morphology and mechanical properties of natural FRP composites: Plant-based jute vs. mineral-based basalt. Composites Part B: Engineering. 2018; 153: 418–427.

[3]Li J, Kasal B. Degradation mechanism of the wood-cell wall surface in a cement environment measured by atomic force microscopy. Journal of Materials in Civil Engineering. 2023; 35(7): 04023149.

[4]Wu H, Shen A, Cheng Q, et al. A review of recent developments in application of plant fibers as reinforcements in concrete. Journal of Cleaner Production. 2023; 413: 137675.

[5]Li H, Zhang Y, Shen W. Investigation on the microstructure and mechanical properties of natural fiber-reinforced cement composites. Construction and Building Materials. 2023; 365: 130042.

[6]Memon SA, Khan S, Wahid I, et al. Evaluating the Effect of Calcination and Grinding of Corn Stalk Ash on Pozzolanic Potential for Sustainable Cement-Based Materials. Advances in Materials Science and Engineering. 2020; 2020(1). doi: 10.1155/2020/1619480

[7]Khan MFS, Akbar M, Xu Z, et al. A review on the role of pretreatment technologies in the hydrolysis of lignocellulosic biomass of corn stover. Biomass and Bioenergy. 2021; 155: 106276.

[8]Gamboa O, Leonardo J, Pérez SPM, et al. Effect of Corn Stover Ash Reinforced with Cabuya Fiber on the Mechanical Properties of Concrete. Journal of Sustainable Architecture and Civil Engineering. 2024; 35(2): 103–116.

[9]Stel’makh SA, Beskopylny AN, Shcherban EM, et al. Influence of Corn Cob Ash Additive on the Structure and Properties of Cement Concrete. Construction Materials and Products. 2024; 7(3): 2. doi: 10.58224/2618-7183-2024-7-3-2

[10]Li Q, Zhao Y, Chen H, et al. Effect of Cornstalk Ash on the Microstructure of Cement-Based Material Under Sulfate Attack. IOP Conference Series: Earth and Environmental Science. 2019; 358(5): 052010. doi: 10.1088/1755-1315/358/5/052010

[11]Shakouri M, Exstrom C, Ramanathan S, et al. Hydration, Strength, and Durability of Cementitious Materials Incorporating Untreated Corn Cob Ash. Construction and Building Materials. 2020; 243: 118171. doi: 10.1016/j.conbuildmat.2020.118171

[12]de Lima CPF, Cordeiro G. Evaluation of Corn Straw Ash as Supplementary Cementitious Material: Effect of Acid Leaching on Its Pozzolanic Activity. Cement. 2021; 4: 100007. doi: 10.1016/J.CEMENT.2021.100007

[13]Dewi SH, Mildawati R, Perdana T. The Benefits of Adding Corn Stalk Ash as a Substitution of Some Cement Against Compressive Strength Concrete. Journal of Geoscience, Engineering, Environment, and Technology. 2019; 4(3): 208. doi: 10.25299/jgeet.2019.4.3.2966

[14]da Costa FBP, Righi DP, Graeff AG, et al. Experimental Study of Some Durability Properties of ECC with a More Environmentally Sustainable Rice Husk Ash and High Tenacity Polypropylene Fibers. Construction and Building Materials. 2019; 213: 505–513. doi: 10.1016/j.conbuildmat.2019.04.092

[15]Mohan SPC. Effect of Artificial Fibers and Corn Cob Ash on Mechanical Behavior of High Performance Concrete. Polish Journal of Environmental Studies. 2022; 31(4): 3713–3721. doi: 10.15244/pjoes/146991

[16]Tan C, Jiang X, Qiang X, et al. Flexural Performance of Carbon Fiber-Reinforced Polymer Prestressed Spun High-Strength Concrete Pile. Applied Sciences. 2024; 14(16): 7170. doi: 10.3390/app14167170

[17]Charitha V, Athira VS, Jittin V, et al. Use of Different Agro-Waste Ashes in Concrete for Effective Upcycling of Locally Available Resources. Construction and Building Materials. 2021; 285: 122851. doi: 10.1016/j.conbuildmat.2021.122851

[18]Ahmed A, Hyndman F, Kamau J, et al. Rice Husk Ash as a Cement Replacement in High Strength Sustainable Concrete. Materials Science Forum. 2020; 1007: 90–98. doi: 10.4028/www.scientific.net/msf.1007.90

[19]Alberti MG, Enfedaque A, Faria DMV, et al. The Potential of Fiber-Reinforced Concrete to Reduce the Environmental Impact of Concrete Construction. Applied Sciences. 2024; 14(15): 6629. doi: 10.3390/app14156629

[20]Silva G, Kim S, Aguilar R, et al. Natural Fibers as Reinforcement Additives for Geopolymers–A Review of Potential Eco-Friendly Applications to the Construction Industry. Sustainable Materials and Technologies. 2020; 23: e00132. doi: 10.1016/j.susmat.2019.e00132

[21]Balea A, Fuente E, Blanco A, et al. Nanocelluloses: Natural-based materials for fiber-reinforced cement composites. A critical review. Polymers. 2019; 11(3): 518.

[22]Amin MN, Ahmad W, Khan K, Ahmad A. A comprehensive review of types, properties, treatment methods and application of plant fibers in construction and building materials. Materials. 2022; 15(12): 4362.

[23]Mohd Basri MS, Abdul Karim Shah NN, Sulaiman A, et al. Progress in the valorization of fruit and vegetable wastes: Active packaging, biocomposites, by-products, and innovative technologies used for bioactive compound extraction. Polymers. 2021; 13(20), 3503.

[24]Guo A, Sun Z, Feng H, et al. (2023). State-of-the-art review on the use of lignocellulosic biomass in cementitious materials. Sustain. Struct. 2023; 3(1): 000023.

[25]Li Q, Ibrahim L, Zhou W, et al. Treatment methods for plant fibers for use as reinforcement in cement-based materials. Cellulose. 2021; 28(9): 5257-5268.

[26]Vinod A, Sanjay MR. Fatigue and thermo-mechanical properties of chemically treated Morinda citrifolia fiber-reinforced bio-epoxy composite: a sustainable green material for cleaner production. Journal of Cleaner Production. 2021; 326: 129411.

[27]Boumaaza M, Belaadi A, Bourchak M. The effect of alkaline treatment on mechanical performance of natural fibers-reinforced plaster: Optimization using RSM. Journal of Natural fibers. 2021; 18(12): 2220-2240.

[28]Akinyemi BA, Adesina A. Utilization of polymer chemical admixtures for surface treatment and modification of cellulose fibres in cement-based composites: a review. Cellulose. 2021; 28(3): 1241-1266.

[29]Sari NH, Wardana ING, Irawan YS, Siswanto E. The effect of sodium hydroxide on chemical and mechanical properties of corn husk fiber. Oriental Journal of Chemistry. 2017; 33(6): 3037–3042.

[30]Shah I, Jing L, Fei ZM, et al. A review on chemical modification by using sodium hydroxide (NaOH) to investigate the mechanical properties of sisal, coir and hemp fiber reinforced concrete composites. Journal of Natural Fibers. 2022; 19(13): 5133–5151.

[31]Ratna AS, Ghosh A, Mukhopadhyay S. Advances and prospects of corn husk as a sustainable material in composites and other technical applications. Journal of cleaner production. 2022; 371: 133563.

[32]Sari NH, Suteja S, Fudholi A, et al. Evaluation of impact, thermo‐physical properties, and morphology of cornhusk fiber‐reinforced polyester composites. Polymer Composites. 2022; 43(5): 2771–2778.

Copyright (c) 2025 Author(s)

This work is licensed under a Creative Commons Attribution 4.0 International License.