Building materials alternative approaches: A bibliometric and review approach

Abstract

In this paper, we develop a global vision of environmental impact with alternative building materials in architectural design. A bibliometric study is based on 1827 scientific research publications on alternative materials produced between 1998 and 2022. More than 90% of these documents have been published in the last ten years. This bibliometric study goal is to develop a systemic approach for the characterisation of alternative solutions in the context of scarce resource context and climate change. This study highlights three different approaches: 1) an ‘integrative’ approach that develops an implementation approach combining environmental concerns and design teams’ own working methods in the selection of materials; 2) an ‘additive’ approach that selects some environmental criteria (carbon footprint and energy consumption) in addition to implementation issues; 3) a ‘subtractive’ approach that focuses solely on implementation issues.

References

[1]Brown JH, Burger JR, Burnside WR, et al. Macroecology meets macroeconomics: Resource scarcity and global sustainability. Ecological Engineering. 2014; 65: 24-32. doi: 10.1016/j.ecoleng.2013.07.071

[2]Ruuska A, Häkkinen T. Material Efficiency of Building Construction. Buildings. 2014; 4(3): 266-294. doi: 10.3390/buildings4030266

[3]Hansen K, Braungart M, Mulhall D. Resource Repletionresourcerepletion, Role of Buildings. In: Loftness V, Haase D. (editors). Sustainable Built Environments. Springer; 2013.

[4]Li L. Integrating climate change impact in new building design process: A review of building life cycle carbon emission assessment methodologies. Cleaner Engineering and Technology. 2021; 5: 100286. doi: 10.1016/j.clet.2021.100286

[5]UNEP. Global Status Report for Buildings and Construction 2019. UNEP; 2019.

[6]Zhang X, Wang F. Analysis of embodied carbon in the building life cycle considering the temporal perspectives of emissions: A case study in China. Energy and Buildings. 2017; 155: 404-413. doi: 10.1016/j.enbuild.2017.09.049

[7]Orsini F, Marrone P. Approaches for a low-carbon production of building materials: A review. Journal of Cleaner Production. 2019; 241: 118380. doi: 10.1016/j.jclepro.2019.118380

[8]González MJ, García Navarro J. Assessment of the decrease of CO2 emissions in the construction field through the selection of materials: Practical case study of three houses of low environmental impact. Building and Environment. 2006; 41(7): 902-909. doi: 10.1016/j.buildenv.2005.04.006

[9]Gama EM, Wamuziri S, Sloan B. The use of alternative building materials in developing countries: Addressing challenges faced by stakeholders. In: Proceedings of the World Construction Conference 2012—Global Challenges in Construction Industry; 28-30 June 2012; Colombo, Sri Lanka.

[10]Li X, Qin D, Hu Y, et al. A systematic review of waste materials in cement-based composites for construction applications. Journal of Building Engineering. 2022; 45: 103447. doi: 10.1016/j.jobe.2021.103447

[11]Thomas BS, Yang J, Mo KH, et al. Biomass ashes from agricultural wastes as supplementary cementitious materials or aggregate replacement in cement/geopolymer concrete: A comprehensive review. Journal of Building Engineering. 2021; 40: 102332. doi: 10.1016/j.jobe.2021.102332

[12]Salas DA, Ramirez AD, Rodríguez CR, et al. Environmental impacts, life cycle assessment and potential improvement measures for cement production: a literature review. Journal of Cleaner Production. 2016; 113: 114-122. doi: 10.1016/j.jclepro.2015.11.078

[13]Jannat N, Latif Al-Mufti R, Hussien A, et al. Utilisation of nut shell wastes in brick, mortar and concrete: A review. Construction and Building Materials. 2021; 293: 123546. doi: 10.1016/j.conbuildmat.2021.123546

[14]Amran M, Murali G, Khalid NHA, et al. Slag uses in making an ecofriendly and sustainable concrete: A review. Construction and Building Materials. 2021; 272: 121942. doi: 10.1016/j.conbuildmat.2020.121942

[15]Ramachandran D. Green Concrete mix using solid waste and nanoparticles as alternatives—A review. Construction and Building Materials. 2018; 162: 96-103. doi: 10.1016/j.conbuildmat.2017.11.174

[16]Ramos Huarachi DA, Gonçalves G, de Francisco AC, et al. Life cycle assessment of traditional and alternative bricks: A review. Environmental Impact Assessment Review. 2020; 80: 106335. doi: 10.1016/j.eiar.2019.106335

[17]Sotayo A, Bradley D, Bather M, et al. Review of state of the art of dowel laminated timber members and densified wood materials as sustainable engineered wood products for construction and building applications. Developments in the Built Environment. 2020; 1: 100004. doi: 10.1016/j.dibe.2019.100004

[18]Petersen AK, Solberg B. Environmental and economic impacts of substitution between wood products and alternative materials: a review of micro-level analyses from Norway and Sweden. Forest Policy and Economics. 2005; 7: 249-259.

[19]Li Y, Zhang Y, Yang Z, et al. Waterborne coatings with sub-ambient cooling under direct sunlight-part I: Optical properties and cooling effect measurements. Solar Energy Materials and Solar Cells. 2020; 217: 110672. doi: 10.1016/j.solmat.2020.110672

[20]Guldentops G, Ardito G, Tao M, et al. A numerical study of adaptive building enclosure systems using solid-solid phase change materials with variable transparency. Energy and Buildings. 2018; 167: 240-252. doi: 10.1016/j.enbuild.2018.02.054

[21]Sameer H, Bringezu S. Life cycle input indicators of material resource use for enhancing sustainability assessment schemes of buildings. Journal of Building Engineering. 2019; 21: 230-242. doi: 10.1016/j.jobe.2018.10.010

[22]Yousefi M, Khandestani R, Gharaei-Moghaddam N. Flexural behavior of reinforced concrete beams made of normal and polypropylene fiber-reinforced concrete containing date palm leaf ash. Structures. 2022; 37: 1053-1068. doi: 10.1016/j.istruc.2022.01.067

[23]Ahmad MR, Chen B, Yousefi Oderji S, et al. Development of a new bio-composite for building insulation and structural purpose using corn stalk and magnesium phosphate cement. Energy and Buildings. 2018; 173: 719-733. doi: 10.1016/j.enbuild.2018.06.007

[24]Wang Y, Rasheed R, Jiang F, et al. Life cycle assessment of a novel biomass-based aerogel material for building insulation. Journal of Building Engineering. 2021; 44: 102988. doi: 10.1016/j.jobe.2021.102988

[25]Teoh WP, Chee SY, Habib NZ, et al. Recycling of treated alum sludge and glycerine pitch in the production of eco-friendly roofing tiles: Physical properties, durability, and leachability. Journal of Building Engineering. 2022; 52: 104387. doi: 10.1016/j.jobe.2022.104387

[26]Belfiore CM, Amato C, Pezzino A, et al. An end of waste alternative for volcanic ash: A resource in the manufacture of ceramic tiles. Construction and Building Materials. 2020; 263: 120118. doi: 10.1016/j.conbuildmat.2020.120118

[27]Ayikoe Tettey UY, Dodoo A, Gustavsson L. Carbon balances for a low energy apartment building with different structural frame materials. Energy Procedia. 2019; 158: 4254-4261. doi: 10.1016/j.egypro.2019.01.801

[28]Martínez-García C, González-Fonteboa B, Carro-López D, et al. Assessment of mussel shells building solutions: A real-scale application. Journal of Building Engineering. 2021; 44: 102635. doi: 10.1016/j.jobe.2021.102635

[29]Beattie C. Decarbonising new city precincts: A case study in Perth, Western Australia. Renewable Energy. 2014; 67: 64-72. doi: 10.1016/j.renene.2013.11.042

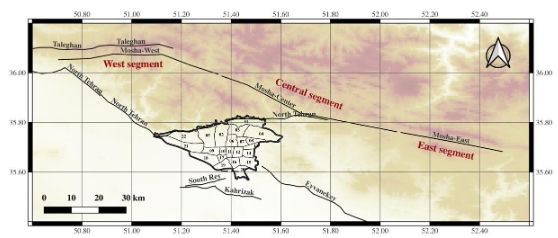

[30]Reza B, Sadiq R, Hewage K. Sustainability assessment of flooring systems in the city of Tehran: An AHP-based life cycle analysis. Construction and Building Materials. 2011; 25(4): 2053-2066. doi: 10.1016/j.conbuildmat.2010.11.041

[31]Van Eck NJ, Waltman L. Visualizing bibliometric networks. In: Ding Y, Rousseau R, Wolfram D (editors). Measuring Scholarly Impact: Methods and Practice. Springer International Publishing; 2014.

[32]van Eck NJ, Waltman L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics. 2009; 84(2): 523-538. doi: 10.1007/s11192-009-0146-3

[33]Det Udomsap A, Hallinger P. A bibliometric review of research on sustainable construction, 1994-2018. Journal of Cleaner Production. 2020; 254: 120073. doi: 10.1016/j.jclepro.2020.120073

[34]Santos WF, Quattrone M, John VM, et al. Roughness, wettability and water absorption of water repellent treated recycled aggregates. Construction and Building Materials. 2017; 146: 502-513. doi: 10.1016/j.conbuildmat.2017.04.012

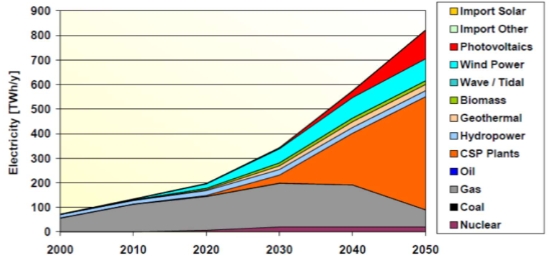

[35]Zhao H xiang, Magoulès F. A review on the prediction of building energy consumption. Renewable and Sustainable Energy Reviews. 2012; 16(6): 3586-3592. doi: 10.1016/j.rser.2012.02.049

[36]Laurie AP. Building Materials made of Waste Materials. Nature. 1923; 112(2826): 956-957. doi: 10.1038/112956b0

[37]Aureliano Fd’S, Costa AApF, Júnior IF, Pedroso Rd’O. Manufacture of structural blocks of concrete with waste tire rubbers. Procedia Manufacturing. 2019; 38: 464-470. doi: 10.1016/j.promfg.2020.01.059

[38]Galimshina A, Moustapha M, Hollberg A, et al. Bio-based materials as a robust solution for building renovation: A case study. Applied Energy. 2022; 316: 119102. doi: 10.1016/j.apenergy.2022.119102

[39]Palumbo M, Lacasta AM, Giraldo MP, et al. Bio-based insulation materials and their hygrothermal performance in a building envelope system (ETICS). Energy and Buildings. 2018; 174: 147-155. doi: 10.1016/j.enbuild.2018.06.042

[40]Žigart M, Kovačič Lukman R, Premrov M, et al. Environmental impact assessment of building envelope components for low-rise buildings. Energy. 2018; 163: 501-512. doi: 10.1016/j.energy.2018.08.149

[41]Zeitz A, Griffin CT, Dusicka P. Comparing the embodied carbon and energy of a mass timber structure system to typical steel and concrete alternatives for parking garages. Energy and Buildings. 2019; 199: 126-133. doi: 10.1016/j.enbuild.2019.06.047

[42]Cusenza MA, Guarino F, Longo S, et al. An integrated energy simulation and life cycle assessment to measure the operational and embodied energy of a Mediterranean net zero energy building. Energy and Buildings. 2022; 254: 111558. doi: 10.1016/j.enbuild.2021.111558

[43]Zawrah MF, Gado RA, Feltin N, et al. Recycling and utilization assessment of waste fired clay bricks (Grog) with granulated blast-furnace slag for geopolymer production. Process Safety and Environmental Protection. 2016; 103: 237-251. doi: 10.1016/j.psep.2016.08.001

[44]Corinaldesi V, Giuggiolini M, Moriconi G. Use of rubble from building demolition in mortars. Waste Management. 2002; 22: 893-899. doi: 10.1016/S0956-053X(02)00087-9

[45]Bisht A. Sand futures: Post-growth alternatives for mineral aggregate consumption and distribution in the global south. Ecological Economics. 2022; 191: 107233. doi: 10.1016/j.ecolecon.2021.107233

[46]Bunzel F, Wisner G, Stammen E, et al. Structural sandwich composites out of wood foam core and textile reinforced concrete sheets for versatile and sustainable use in the building industry. Materials Today: Proceedings. 2020; 31: S296-S302. doi: 10.1016/j.matpr.2020.01.382

[47]Göswein V, Silvestre JD, Lamb S, et al. Invasive alien plants as an alternative resource for concrete production—multi-scale optimization including carbon compensation, cleared land and saved water runoff in South Africa. Resources, Conservation and Recycling. 2021; 167: 105361. doi: 10.1016/j.resconrec.2020.105361

[48]Humbert PS, Castro-Gomes JP, Savastano H. Clinker-free CO2 cured steel slag based binder: Optimal conditions and potential applications. Construction and Building Materials. 2019; 210: 413-421. doi: 10.1016/j.conbuildmat.2019.03.169

[49]Vashistha P, Singh SK, Dutt D, et al. Sustainable utilization of paper mill solid wastes via synthesis of nano silica for production of belite based clinker. Journal of Cleaner Production. 2019; 224: 557-565. doi: 10.1016/j.jclepro.2019.03.207

[50]Akbar A, Farooq F, Shafique M, et al. Sugarcane bagasse ash-based engineered geopolymer mortar incorporating propylene fibers. Journal of Building Engineering. 2021; 33: 101492. doi: 10.1016/j.jobe.2020.101492

[51]Alonso MM, Gascó C, Morales MM, et al. Olive biomass ash as an alternative activator in geopolymer formation: A study of strength, radiology and leaching behaviour. Cement and Concrete Composites. 2019; 104: 103384. doi: 10.1016/j.cemconcomp.2019.103384

[52]Bajracharya RM, Manalo AC, Karunasena W, et al. An overview of mechanical properties and durability of glass-fibre reinforced recycled mixed plastic waste composites. Materials & Design (1980-2015). 2014; 62: 98-112. doi: 10.1016/j.matdes.2014.04.081

[53]Binici H, Aksogan O, Demirhan C. Mechanical, thermal and acoustical characterizations of an insulation composite made of bio-based materials. Sustainable Cities and Society. 2016; 20: 17-26. doi: 10.1016/j.scs.2015.09.004

[54]Suksiripattanapong C, Jenpiyapong K, Tiyasangthong S, et al. Mechanical and thermal properties of lateritic soil mixed with cement and polymers as a non-bearing masonry unit. Case Studies in Construction Materials. 2022; 16: e00962. doi: 10.1016/j.cscm.2022.e00962

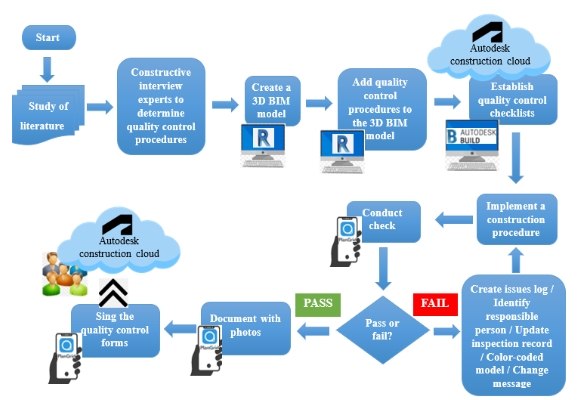

[55]Ahmad T, Aibinu A, Thaheem MJ. BIM-based Iterative Tool for Sustainable Building Design: A Conceptual Framework. Procedia Engineering. 2017; 180: 782-792. doi: 10.1016/j.proeng.2017.04.239

[56]Ahmed N, Abdel-Hamid M, Abd El-Razik MM, et al. Impact of sustainable design in the construction sector on climate change. Ain Shams Engineering Journal. 2021; 12(2): 1375-1383. doi: 10.1016/j.asej.2020.11.002

[57]Wernet G, Bauer C, Steubing B, et al. The ecoinvent database version 3 (part I): overview and methodology. The International Journal of Life Cycle Assessment. 2016; 21(9): 1218-1230. doi: 10.1007/s11367-016-1087-8

[58]IEA. Global Status Report for Buildings and Construction 2019. IEA; 2019.

[59]Predeanu G, Slăvescu V, Bălănescu M, et al. Coal bottom ash processing for capitalization according to circular economy concept. Minerals Engineering. 2021; 170: 107055. doi: 10.1016/j.mineng.2021.107055

Copyright (c) 2024 Nathalie Tornay

This work is licensed under a Creative Commons Attribution 4.0 International License.