Effects of pyrolyzed Buxus sempervirens ingredient as micro and bio fillers on polystyrene: Spectroscopic characteristics

Abstract

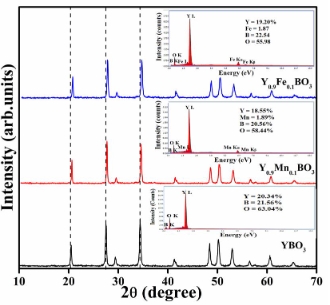

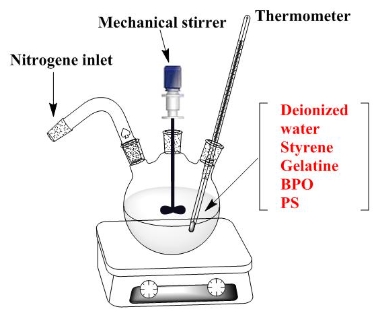

In this study, Buxus sempervirens leaf ingredient (LP) and the carbon (LC) and the ash (LA) were obtained, which are the bio-originated materials. Carbon and ash obtained from this natural plant were prepared by heating and pyrolysis for 2 h at 250 ℃ and 700 ℃, respectively. Then, the solution casting method was used to prepare the composites of these bio-additives with polystyrene. Next, the effects of the additives on diffuse reflectance spectroscopy (DRS) and X-ray diffraction (XRD) spectra of polystyrene were investigated. In addition, the additives led to noticeable changes in X-ray diffraction results, implying a change in the morphology of the polymer. All of these observations imply the uniform formation of the polystyrene (PS) composites with the micro and bio-fillers.

References

[1]Nazarpour-Fard H, Rad-Moghadam K, Shirini F. Improved hydrophobic and thermal stability of polyvinylpyrrolidone composites with the ingredients of Buxus sempervirens. Applied Chemistry 2018; 13(47): 69–82. doi: 10.22075/CHEM.2018.2900

[2]Nazarpour-Fard H. Polyvinylpyrrolidone and polystyrene composites based on economical high quality biofillers derived from rice husk: Spectroscopic and hydrophilic investigations. Polyolefins Journal 2023; 10(1): 45–57. doi: 10.22063/POJ.2022.3221.1232

[3]Nazarpour-Fard H. Composites of polyvinylpyrrolidone and polystyrene with rice husk ash as a bio and silica-rich material: Thermal characteristics and water vapor absorption ability. Epitoanyag—Journal of Silicate Based and Composite Materials 2022; 74(6). doi: 10.14382/epitoanyag-jsbcm.2022.33

[4]Nazarpour-Fard H, Rad-Moghadam K, Shirini F, et al. Novel improvements in thermal and hydrophobic properties of chitosan reinforced by rice husk ash. Polymers from Renewable Resources 2016; 7(4): 115–133. doi: 10.1177/204124791600700401

[5]Nazarpour-Fard H. Rice husk ash: Economical and high-quality natural-based reinforcing filler for linear low-density and high-density polyethylene. Polymers from Renewable Resources 2022; 13(4): 206–222. doi: 10.1177/20412479221128965

[6]Chaudhary V, Sharma S. Suspension polymerization technique: Parameters affecting polymer properties and application in oxidation reactions. Journal of Polymer Research 2019; 26(5). doi: 10.1007/s10965-019-1767-8

[7]Huang J, Zhao Z, Chen T, et al. Preparation of highly dispersed expandable graphite/polystyrene composite foam via suspension polymerization with enhanced fire retardation. Carbon 2019; 146: 503–512. doi: 10.1016/j.carbon.2019.02.029

[8]Das M, Sethy PP, Sundaray B. EMI shielding performance of graphene oxide reinforced polyaniline/polystyrene solution cast thin films. Synthetic Metals 2023; 296: 117369. doi: 10.1016/j.synthmet.2023.117369

[9]Yadav NP, Sahu BB, Mahaling RN, et al. Superior dielectric and electrical characteristics of poly(methylmethacrylate) (PMMA)-BiFeO3-Polystyrene-2% divinyl benzene (PDB) composites. Optik 2023; 277: 170695. doi: 10.1016/j.ijleo.2023.170695

[10]Bavasso I, Marzi D, Bracciale MP, et al. Plant waste as green reinforcement for polymer composites: A case study of Pteris vittata roots. Journal of Natural Fibers 2022; 20(1). doi: 10.1080/15440478.2022.2135669

[11]Kinyanjui Muiruri J, Chee Chuan Yeo J, Yun Debbie Soo X, et al. Recent advances of sustainable short-chain length polyhydroxyalkanoates (Scl-PHAs)—Plant biomass composites. European Polymer Journal 2023; 187: 111882. doi: 10.1016/j.eurpolymj.2023.111882

[12]Merino D, Bellassi P, Paul UC, et al. Assessment of chitosan/pectin-rich vegetable waste composites for the active packaging of dry foods. Food Hydrocolloids 2023; 139: 108580. doi: 10.1016/j.foodhyd.2023.108580

[13]Cherkashina NI, Pavlenko ZV, Pushkarskaya DV, et al. Synthesis and properties of polystyrene composite material with hazelnut shells. Polymers 2023; 15(15): 3212. doi: 10.3390/polym15153212

[14]Slobodian P, Pavlínek V, Lengálová A, et al. Polystyrene/multi-wall carbon nanotube composites prepared by suspension polymerization and their electrorheological behavior. Current Applied Physics 2009; 9(1): 184–188. doi: 10.1016/j.cap.2008.01.008

[15]Chen CM, Hsieh TE, Ju MY. Effects of polydispersity index and molecular weight on crystallization kinetics of syndiotactic polystyrene (sPS). Journal of Alloys and Compounds 2009; 480(2): 658–661. doi: 10.1016/j.jallcom.2009.02.003

Copyright (c) 2023 Hamed Nazarpour Fard

This work is licensed under a Creative Commons Attribution 4.0 International License.