Examination of surface contamination and impurities in tinplate samples, both passivated and non-passivated

Abstract

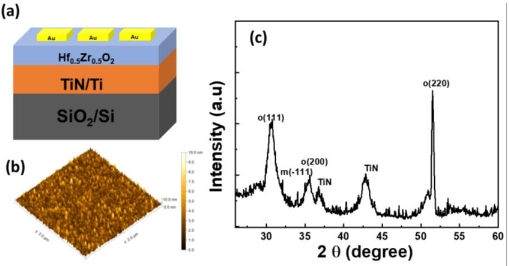

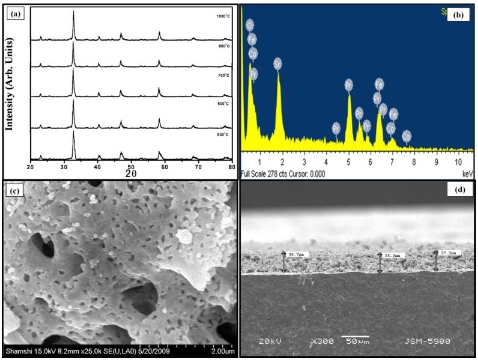

This study examined the surfaces of non-passivated and passivated tinplate samples, as well as the impurities present on them, using SEM, EDS, and GDOES. Additionally, solutions were analyzed using ICP in order to identify any correlations between the elements present in the solutions and on the strip surfaces. The results from GDOES indicated the presence of unwanted elements, such as Sn, S, Cr, N, P, Zn, Fe, Mn, C, and Si, on both the passivated and non-passivated sample surfaces. SEM analysis of the passivated sample revealed light and dark regions in parallel lines, which were observed ahead of the rolling direction. EDS analysis indicated that the light areas were rich in Sn while the dark areas were rich in Fe, and C was identified as an unwanted element in both areas. O and Cr were only found in the dark areas. EDS analysis of the impurities revealed Na, S, Cl, Ca, Mg, Si, N, and Al as unwanted elements. The results suggest that unwanted elements are transferred from the steel strip surface to different solutions in the tinplate line, causing pollution in various solutions.

References

[1]Wester PA. Chapter 3—Hazards, the hazard analysis, and the food safety plan. In: Hazard Analysis and Risk Based Preventative Controls: Building a (Better) Food Safety Plan. Academic Press; 2018. pp. 43–65. doi: 10.1016/B978-0-12-810500-9.00003-5

[2]Akyil C, Akdas G, Afsin P, Ürgen M. Freestanding SnO2 films produced with anodic polarization in acidic media containing colloidal tin hydroxides. Materials Chemistry and Physics 2019; 221: 263–271. doi: 10.1016/j.matchemphys.2018.09.062

[3]Al-Ghamdi S, Rasco B, Tang J, et al. Role of package headspace on multilayer films subjected to high hydrostatic pressure. Packaging Technology and Science 2019; 32(5): 247–257. doi: 10.1002/pts.2432

[4]Ren Y, Huang Z, Wang Y, et al. Friction-induced rapid amorphization in a wear-resistant (CoCrNi)88Mo12 dual-phase medium-entropy alloy at cryogenic temperature. Composites Part B: Engineering 2023; 263: 110833. doi: 10.1016/j.compositesb.2023.110833

[5]Zhou Q, Hua D, Li S, et al. Design and characterization of metallic glass/graphene multilayer with excellent nanowear properties. Friction 2022; 10(11): 1913–1926. doi: 10.1007/s40544-021-0581-6

[6]Melvin C, Jewell E, Miedema J, et al. Identifying interlayer surface adhesion failure mechanisms in tinplate packaging steels. Packaging Technology and Science 2019; 32(7): 345–355. doi: 10.1002/pts.2443

[7]Xu F, Shi Y, Yang J, Yan S. Corrosion failure analysis of lightweight tinplate in protein beverage. IOP Conference Series: Materials Science and Engineering 2019; 538(1): 012018. doi: 10.1088/1757-899X/538/1/012018

[8]Zhao Y, Yin X, Shen P, et al. Passivation and chemical conversion combined multi-elements coating on low Sn-coated steel for corrosion protection. Journal of the Electrochemical Society 2022; 169(8): 082501. doi: 10.1149/1945-7111/ac7efa

[9]Cova Caiazzo F, Brambilla L, Montanari A, Mischler S. Chemical and morphological characterization of commercial tinplate for food packaging. Surface and Interface Analysis 2018; 50(4): 430–440. doi: 10.1002/sia.6386

[10]Wang M, Wang Z, Li D, Li N. Study of topography and distribution state of the nanoscale passivation film on a rough tinplate surface. Coatings 2018; 8(3): 94. doi: 10.3390/coatings8030094

[11]Chen S, Xie L, Xue S. X-ray photoelectron spectroscopy investigation of commercial passivated tinplate surface layer. Applied Surface Science 2013; 276: 454–457. doi: 10.1016/j.apsusc.2013.03.115

[12]Sun J, Qi GC, Tan Y, An CQ. Characterization of chromate conversion film on tinplate substrate by XPS and electrochemistry methods. Surface and Interface Analysis 2009; 41(6): 449–452. doi: 10.1002/sia.3040

[13]Azzerri N, Ingo G, Battistoni C, et al. A critical evaluation of electroanalysis methods for the determination of chromium species in passivation layers on tinplate by X-ray photoelectron spectroscopy. Surface Technology 1984; 21(4): 391–404. doi: 10.1016/0376-4583(84)90137-7

[14]Chang KH, Hurley BL, Pascall MA, Frankel GS. Corrosion in tinplate cans used for food storage, part 3: Effects of cysteine, NaCl, and tomatoes on corrosion of tin, iron, and tinplate. Corrosion 2022; 78(2): 127–141. doi: 10.5006/3963

[15]Cui GF, Wang JH, Li N, Huang XQ. A single precursor pit for pitting corrosion on defect of tinplate alloy layer visualized by atomic force microscopy. Materials Chemistry and Physics 2006; 97(2–3): 488–493. doi: 10.1016/j.matchemphys.2005.08.052

[16]Černík M, Gburík R, Hrabčáková L, Vranec P. Texture analysis of tinplate steel and its application in production of double reduced high strength tinplate grades with controlled earing properties. IOP Conference Series: Materials Science and Engineering 2015; 82(1): 012108. doi: 10.1088/1757-899X/82/1/012108

Copyright (c) 2023 Amirhossein Meysami, Reza Amini Najafabadi, Ehsan Nemati Varnoosfaderani, Erfan Aghili, Aliasghar Foroughifar

This work is licensed under a Creative Commons Attribution 4.0 International License.