Preparation of nascent disentangled ultra-high molecular weight polyethylene based on Ziegler-Natta catalyst

Abstract

Ziegler-Natta (Z-N) catalysts hold great significance in the industrial production of ultrahigh molecular weight polyethylene (UHMWPE), given that their outstanding efficacy, profound impact on the molecular weight (MW) of UHMWPE, and extensive industrial applications are highly conspicuous. However, the UHMWPE prepared by Z-N catalyst is usually highly entangled. Considering chain entanglement is essential for altering the processability and mechanical characteristics of nascent UHMWPE, the synthesis of disentangled UHMWPE (dis-UHMWPE) is essential for industrial scalability, therefore holding considerable practical importance. This review summarized recent progress in optimizing Z-N catalysts for the synthesis of dis-UHMWPE, providing a comprehensive overview of research advancements, clarifying polymerization settings, linking polymer structure and activity, and introducing design principles for polymerization techniques. Moreover, the overarching objective is to reveal the principles behind material preparation methods and potentiate the application prospects of UHMWPE materials, therein propelling the advancement of related fields.

References

[1]Zakaria M, Bhuiyan MAR, Hossain MdS, et al. Advances of polyolefins from fiber to nanofiber: fabrication and recent applications. Discover Nano. 2024; 19(1). doi: 10.1186/s11671-023-03945-y

[2]Faruk O, Yang Y, Zhang J, et al. A Comprehensive Review of Ultrahigh Molecular Weight Polyethylene Fibers for Applications Based on Their Different Preparation Techniques. Hu X, ed. Advances in Polymer Technology. 2023; 2023: 1–16. doi: 10.1155/2023/6656692

[3]Wang Y, Fu J, Yu J, et al. Dissolving of Ultra-high Molecular Weight Polyethylene Assisted Through Supercritical Carbon Dioxide to Enhance the Mechanical Properties of Fibers. Advanced Fiber Materials. 2021; 4(2): 280–292. doi: 10.1007/s42765-021-00107-6

[4]Shelly D, Lee SY, Park SJ. Compatibilization of ultra-high molecular weight polyethylene (UHMWPE) fibers and their composites for superior mechanical performance: A concise review. Composites Part B: Engineering. 2024; 275: 111294. doi: 10.1016/j.compositesb.2024.111294

[5]Duan Y, Li L, Shen Z, et al. Engineering Metal-Organic-Framework (MOF)-Based Membranes for Gas and Liquid Separation. Membranes. 2023; 13(5): 480. doi: 10.3390/membranes13050480

[6]Hussain M, Naqvi RA, Abbas N, et al. Ultra-High-Molecular-Weight-Polyethylene (UHMWPE) as a Promising Polymer Material for Biomedical Applications: A Concise Review. Polymers. 2020; 12(2): 323. doi: 10.3390/polym12020323

[7]Cheung SY, Wen W, Gao P. Disentanglement and micropore structure of UHMWPE in an athermal solvent. Polymer Engineering & Science. 2014; 55(5): 1177–1186. doi: 10.1002/pen.23989

[8]Li L, Duan Y. Engineering Polymer-Based Porous Membrane for Sustainable Lithium-Ion Battery Separators. Polymers. 2023; 15(18): 3690. doi: 10.3390/polym15183690

[9]Yuan H, Long C, Yu J, et al. Synthesis of Granular Hydroxy-Functionalized Ultra-high-molecular-weight Polyethylene and Its Fiber Properties. Advanced Fiber Materials. 2022; 4(4): 786–794. doi: 10.1007/s42765-022-00136-9

[10]Wu SL, Qiao J, Guan J, et al. Nascent disentangled UHMWPE: Origin, synthesis, processing, performances and applications. European Polymer Journal. 2023; 184: 111799. doi: 10.1016/j.eurpolymj.2022.111799

[11]Xing C, Chen L, Gao J, et al. Structural evolution of low-entangled UHMWPE gel films with reserved shish crystals and different entanglement degrees during stretching. Polymer. 2024; 312: 127592. doi: 10.1016/j.polymer.2024.127592

[12]Huang Q. When Polymer Chains Are Highly Aligned: A Perspective on Extensional Rheology. Macromolecules. 2022; 55(3): 715–727. doi: 10.1021/acs.macromol.1c02262

[13]Yilmaz G, Uslu E. A new approach for high-quality production of UHMWPE by applying powder vibration densification before sintering. Powder Technology. 2023; 427: 118741. doi: 10.1016/j.powtec.2023.118741

[14]Khalil Y, Hopkinson N, Kowalski A, et al. Characterisation of UHMWPE Polymer Powder for Laser Sintering. Materials. 2019; 12(21): 3496. doi: 10.3390/ma12213496

[15]Goodridge RD, Hague RJM, Tuck CJ. An empirical study into laser sintering of ultra-high molecular weight polyethylene (UHMWPE). Journal of Materials Processing Technology. 2010; 210(1): 72–80. doi: 10.1016/j.jmatprotec.2009.08.016

[16]O’Connor TC, Hopkins A, Robbins MO. Stress Relaxation in Highly Oriented Melts of Entangled Polymers. Macromolecules. 2019; 52(22): 8540–8550. doi: 10.1021/acs.macromol.9b01161

[17]Patel K, Chikkali SH, Sivaram S. Ultrahigh molecular weight polyethylene: Catalysis, structure, properties, processing and applications. Progress in Polymer Science. 2020; 109: 101290. doi: 10.1016/j.progpolymsci.2020.101290

[18]Houben SJA, Verpaalen RCP, Engels TAP. Processing and Properties of Melt Processable UHMW‐PE Based Fibers Using Low Molecular Weight Linear Polyethylene’s. Macromolecular Materials and Engineering. 2020; 305(10). doi: 10.1002/mame.202000360

[19]Liu J, Jin T, Qin S, et al. Study on the synergistic effect of additives on the processing performance of UHMWPE/HDPE blends. Journal of Applied Polymer Science. 2024; 141(21). doi: 10.1002/app.55421

[20]Vadivel HS, Bek M, Šebenik U, et al. Do the particle size, molecular weight, and processing of UHMWPE affect its thermomechanical and tribological performance? Journal of Materials Research and Technology. 2021; 12: 1728–1737. doi: 10.1016/j.jmrt.2021.03.087

[21]Li L, Kong F, Xiao A, et al. Constructing polyolefin-based lithium-ion battery separators membrane for energy storage and conversion. Energy Storage and Conversion. 2024; 2(4): 1631. doi: 10.59400/esc1631

[22]Li L, Kong F, Xiao A, et al. Current research status of high-performance UHMWPE fiber: A review. Materials Technology Reports. 2024; 2(2): 1518. doi: 10.59400/mtr1518

[23]Kim T, Drakopoulos SX, Ronca S, et al. Origin of high thermal conductivity in disentangled ultra-high molecular weight polyethylene films: ballistic phonons within enlarged crystals. Nature Communications. 2022; 13(1). doi: 10.1038/s41467-022-29904-2

[24]Zhang Z, Kang X, Jiang Y, et al. Access to Disentangled Ultrahigh Molecular Weight Polyethylene via a Binuclear Synergic Effect. Angewandte Chemie International Edition. 2022; 62(4). doi: 10.1002/anie.202215582

[25]Tao G, Chen Y, Mu J, et al. Exploring the entangled state and molecular weight ofUHMWPEon the microstructure and mechanical properties ofHDPE/UHMWPEblends. Journal of Applied Polymer Science. 2021; 138(30). doi: 10.1002/app.50741

[26]Rastogi S, Yao Y, Ronca S, et al. Unprecedented High-Modulus High-Strength Tapes and Films of Ultrahigh Molecular Weight Polyethylene via Solvent-Free Route. Macromolecules. 2011; 44(14): 5558–5568. doi: 10.1021/ma200667m

[27]Li W, Guan C, Xu J, et al. Disentangled UHMWPE/POSS nanocomposites prepared by ethylene in situ polymerization. Polymer. 2014; 55(7): 1792–1798. doi: 10.1016/j.polymer.2014.02.023

[28]Li W, Yang H, Zhang J, et al. Immobilization of isolated FI catalyst on polyhedral oligomeric silsesquioxane-functionalized silica for the synthesis of weakly entangled polyethylene. Chemical Communications. 2016; 52(74): 11092–11095. doi: 10.1039/c6cc04814e

[29]Pandey A, Champouret Y, Rastogi S. Heterogeneity in the Distribution of Entanglement Density during Polymerization in Disentangled Ultrahigh Molecular Weight Polyethylene. Macromolecules. 2011; 44(12): 4952–4960. doi: 10.1021/ma2003689

[30]Hui L, Yue Z, Yang H, et al. Influence of the Fragmentation of POSS-Modified Heterogeneous Catalyst on the Formation of Chain Entanglements. Industrial & Engineering Chemistry Research. 2018; 57(29): 9400–9406. doi: 10.1021/acs.iecr.8b01641

[31]Yao Y, Jiang S, Rastogi S. 13C Solid State NMR Characterization of Structure and Orientation Development in the Narrow and Broad Molar Mass Disentangled UHMWPE. Macromolecules. 2014; 47(4): 1371–1382. doi: 10.1021/ma402232c

[32]Oleynik IV, Shundrina IK, Oleyinik II. Highly active titanium(IV) dichloride FI catalysts bearing a diallylamino group for the synthesis of disentangled UHMWPE. Polymers for Advanced Technologies. 2020; 31(9): 1921–1934. doi: 10.1002/pat.4917

[33]Rastogi S, Lippits DR, Höhne GWH, et al. The role of the amorphous phase in melting of linear UHMW-PE; implications for chain dynamics. Journal of Physics: Condensed Matter. 2007; 19(20): 205122. doi: 10.1088/0953-8984/19/20/205122

[34]Hawke LGD, Romano D, Rastogi S. Nonequilibrium Melt State of Ultra-High-Molecular-Weight Polyethylene: A Theoretical Approach on the Equilibrium Process. Macromolecules. 2019; 52(22): 8849–8866. doi: 10.1021/acs.macromol.9b01152

[35]Ye C, Yang T, Li Z, et al. Novel determining technique for the entanglement degree of ultra-high molecular weight polyethylene. Materials Letters. 2023; 349: 134783. doi: 10.1016/j.matlet.2023.134783

[36]Li W, Yue Z, Lozovoi A, et al. Heterogeneous distribution of chain mobility in nascent UHMWPE in the less entangled state. Journal of Polymer Research. 2018; 25(11). doi: 10.1007/s10965-018-1637-9

[37]Zhao Y, Liang Y, Yao Y, et al. Chain Dynamics of Partially Disentangled UHMWPE around Melting Point Characterized by 1H Low-Field Solid-State NMR. Polymers. 2023; 15(8): 1910. doi: 10.3390/polym15081910

[38]Zhou J, Zhang X, Zhao S, et al. Chain disentanglement in POSS/UHMWPE composites prepared via in-situ polymerization. Journal of Polymer Research. 2022; 29(3). doi: 10.1007/s10965-022-02909-7

[39]Li W, Hui L, Xue B, et al. Facile high-temperature synthesis of weakly entangled polyethylene using a highly activated Ziegler-Natta catalyst. Journal of Catalysis. 2018; 360: 145–151. doi: 10.1016/j.jcat.2018.01.024

[40]Chen Y, Liang P, Yue Z, et al. Entanglement Formation Mechanism in the POSS Modified Heterogeneous Ziegler–Natta Catalysts. Macromolecules. 2019; 52(20): 7593–7602. doi: 10.1021/acs.macromol.9b00610

[41]Chen M, Chen Y, Li W, et al. Synthesis of Weakly Entangled Ultra-High-Molecular-Weight Polyethylene with a Fine Particle Size. Industrial & Engineering Chemistry Research. 2021; 60(8): 3354–3362. doi: 10.1021/acs.iecr.0c05838

[42]Zhou J, Zhang X, Zhao S, et al. Study on the effects of soluble POSS on chain disentanglement in UHMWPE polymerization. Polymer. 2022; 244: 124561. doi: 10.1016/j.polymer.2022.124561

[43]Guo T, Zhou Q, Chen Y, et al. Preparation of Weakly Entangled and Fine-sized Ultra-High-Molecular Weight Polyethylene by a MgCl2-Based Ziegler–Natta Catalyst. Industrial & Engineering Chemistry Research. 2022; 61(45): 16711–16720. doi: 10.1021/acs.iecr.2c03427

[44]Zhou J, Zhang X, Zhao S, et al. Influence of Modified Ziegler–Natta Catalyst on the Entanglement Behavior and Properties of Ultrahigh-Molecular-Weight Polyethylene (UHMWPE). Industrial & Engineering Chemistry Research. 2022; 61(48): 17512–17523. doi: 10.1021/acs.iecr.2c03275

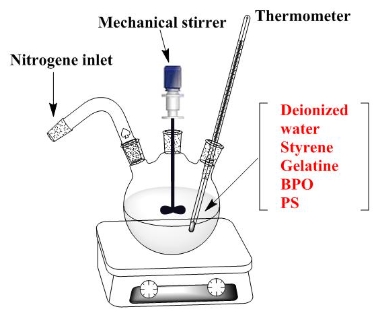

[45]Cao Y, Wu Y, Tang X, et al. Long‐term efficiency for reducing entanglements of nascent polyethylene by a polystyrene‐modified Ziegler‐Natta catalyst. Journal of Applied Polymer Science. 2021; 139(11). doi: 10.1002/app.51790

[46]Chammingkwan P, Bando Y, Mai LTT, et al. Less Entangled Ultrahigh-Molecular-Weight Polyethylene Produced by Nano-Dispersed Ziegler–Natta Catalyst. Industrial & Engineering Chemistry Research. 2021; 60(7): 2818–2827. doi: 10.1021/acs.iecr.0c05432

[47]Wang H, Yan X, Tang X, et al. Contribution of the Initially Entangled State and Particle Size to the Sintering Kinetics of UHMWPE. Macromolecules. 2022; 55(4): 1310–1320. doi: 10.1021/acs.macromol.1c02058

[48]Sellinger A, Laine RM. Silsesquioxanes as Synthetic Platforms. Thermally Curable and Photocurable Inorganic/Organic Hybrids. Macromolecules. 1996; 29(6): 2327–2330. doi: 10.1021/ma951499y

[49]Ayandele E, Sarkar B, Alexandridis P. Polyhedral Oligomeric Silsesquioxane (POSS)-Containing Polymer Nanocomposites. Nanomaterials. 2012; 2(4): 445–475. doi: 10.3390/nano2040445

[50]Romo-Uribe A, Reyes-Mayer A, Paredes-Pérez M, et al. POSS driven chain disentanglements, decreased the melt viscosity and reduced O2 transmission in polyethylene. Polymer. 2019; 165: 61–71. doi: 10.1016/j.polymer.2019.01.024

[51]Chai SC, Xu TY, Cao X, et al. Ultrasmall Nanoparticles Diluted Chain Entanglement in Polymer Nanocomposites. Chinese Journal of Polymer Science. 2019; 37(8): 797–805. doi: 10.1007/s10118-019-2262-8

[52]Guo M, David É, Fréchette M, et al. Polyethylene/polyhedral oligomeric silsesquioxanes composites: Dielectric, thermal and rheological properties. Polymer. 2017; 115: 60–69. doi: 10.1016/j.polymer.2017.03.015

[53]Raftopoulos KN, Pielichowski K. Segmental dynamics in hybrid polymer/POSS nanomaterials. Progress in Polymer Science. 2016; 52: 136–187. doi: 10.1016/j.progpolymsci.2015.01.003

[54]Romo-Uribe A, Lichtenhan J, Reyes-Mayer A, et al. Chain Disentanglements and Oxygen Transmission Reduction in LDPE/POSS Nanocomposites. Influence of POSS Size. Industrial & Engineering Chemistry Research. 2019; 58(29): 13145–13153. doi: 10.1021/acs.iecr.9b01846

[55]Deplancke T, Lame O, Rousset F, et al. Diffusion versus Cocrystallization of Very Long Polymer Chains at Interfaces: Experimental Study of Sintering of UHMWPE Nascent Powder. Macromolecules. 2013; 47(1): 197–207. doi: 10.1021/ma402012f

Copyright (c) 2025 Lei Li, Fanmin Kong, Ang Xiao, Ziling Zhang, Hao Su, Xiaolian Wu, Yutian Duan

This work is licensed under a Creative Commons Attribution 4.0 International License.