3D-printed poly (lactic acid) scaffolds coated with cationic macro-biocide: Investigation of anti-biofilm activity and thermo-mechanical properties

Abstract

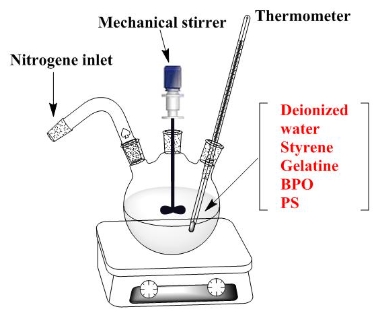

In this study, the primary goal was to combine surface modification and 3D printing technology to create materials with anti-biofilm action. In order to achieve this, first a two-step reaction procedure using ring-opening copolymerization and copper(I)-catalyzed azide-alkyne cycloaddition click reaction was used to successfully fabricate poly (lactic acid) (PLA) bearing quaternary ammonium salt (QAS) as an antimicrobial agent on its backbone at rates of 5% by mole. Then, this synthesized PLA-based (co)polymer dissolved in acetone with a weight percentage of 30% was used to coat 3D-printed PLA by dipping for 10, 30, and 90 s. These coated samples encoded PLA/10/PLA-QAS, PLA/30/PLA-QAS, and PLA/90/PLA-QAS, respectively. The coated PLA scaffolds were then characterized by Fourier transform infrared spectroscopy (FT-IR) and scanning electron microscopy (SEM). Gram-positive (Staphylococcus aureus) and Gram-negative (Escherichia coli) bacteria were used to assess the anti-biofilm activity of the samples. In addition, the thermal and mechanical properties of the samples were examined through differential scanning calorimetry (DSC) and three-point bending tests, respectively. Consequently, covering the 3D-printed PLA surfaces with synthesized antimicrobial polymer prevented the formation of biofilms against both bacteria, and all coated samples showed no toxicity in 25% and 10% extraction mediums. And, it was observed that the antimicrobial polymer solution had a plasticizing effect on the PLA scaffold. As the dipping times increased, the glass transition temperatures of the coated samples decreased. In terms of flexural behaviors, increasing the dipping time also improved the flexural strain of coated PLA scaffolds. These thermo-mechanical results are correlated with SEM morphologies because of the penetration and solution effect of antimicrobial polymer dissolved in acetone.

References

[1]Water JJ, Bohr A, Boetker J, et al. Three-Dimensional Printing of Drug-Eluting Implants: Preparation of an Antimicrobial Polylactide Feedstock Material. Journal of Pharmaceutical Sciences. 2015; 104(3): 1099-1107. doi: 10.1002/jps.24305

[2]Muro-Fraguas I, Sainz-García A, López M, et al. Antibiofilm coatings through atmospheric pressure plasma for 3D printed surgical instruments. Surface and Coatings Technology. 2020; 399: 126163. doi: 10.1016/j.surfcoat.2020.126163

[3]Castro JD, Carneiro E, Marques SM, et al. Surface functionalization of 3D printed structures: Aesthetic and antibiofouling properties. Surface and Coatings Technology. 2020; 386: 125464. doi: 10.1016/j.surfcoat.2020.125464

[4]Zuo M, Pan N, Liu Q, et al. Three-dimensionally printed polylactic acid/cellulose acetate scaffolds with antimicrobial effect. RSC Advances. 2020; 10(5): 2952-2958. doi: 10.1039/c9ra08916k

[5]Pastor-Artigues MM, Roure-Fernández F, Ayneto-Gubert X, et al. Elastic Asymmetry of PLA Material in FDM-Printed Parts: Considerations Concerning Experimental Characterisation for Use in Numerical Simulations. Materials. 2019; 13(1): 15. doi: 10.3390/ma13010015

[6]González-Henríquez CM, Sarabia-Vallejos MA, Rodríguez Hernandez J. Antimicrobial Polymers for Additive Manufacturing. International Journal of Molecular Sciences. 2019; 20(5): 1210. doi: 10.3390/ijms20051210

[7]Otieno DB, Bosire GO, Onyari JM, et al. Comparative analysis of 3D-printed polylactic acid and acrylonitrile butadiene styrene: Experimental and Materials-Studio-based theoretical studies. Journal of Polymer Research. 2022; 29(7). doi: 10.1007/s10965-022-03075-6

[8]Weisman JA, Nicholson JC, Tappa K, et al. Antibiotic and chemotherapeutic enhanced three-dimensional printer filaments and constructs for biomedical applications. International Journal of Nanomedicine. 2015. doi: 10.2147/ijn.s74811

[9]Abd El Aal MI, Awd Allah MM, Abd Alaziz SA, et al. Biodegradable 3D printed polylactic acid structures for different engineering applications: effect of infill pattern and density. Journal of Polymer Research. 2023; 31(1). doi: 10.1007/s10965-023-03852-x

[10]Chen X, Chen G, Wang G, et al. Recent Progress on 3D‐Printed Polylactic Acid and Its Applications in Bone Repair. Advanced Engineering Materials. 2019; 22(4). doi: 10.1002/adem.201901065

[11]Ambrose CG, Clanton TO. Bioabsorbable implants: review of clinical experience in orthopedic surgery. Ann. Biomed. Eng. 2004; 32: 171-177. doi: 10.1023/B:ABME.0000007802.59936.fc

[12]Kumar B, Castro M, Feller JF. Poly (lactic acid)–multi-wall carbon nanotube conductive biopolymer nanocomposite vapour sensors. Sensors and Actuators B: Chemical. 2012; 161(1): 621-628. doi: 10.1016/j.snb.2011.10.077

[13]El Habnouni S, Darcos V, Garric X, et al. Mild Methodology for the Versatile Chemical Modification of Polylactide Surfaces: Original Combination of Anionic and Click Chemistry for Biomedical Applications. Advanced Functional Materials. 2011; 21(17): 3321-3330. doi: 10.1002/adfm.201100412

[14]Rasal RM, Janorkar AV, Hirt DE. Poly (lactic acid) modifications. Progress in Polymer Science. 2010; 35(3): 338-356. doi: 10.1016/j.progpolymsci.2009.12.003

[15]Turalija M, Bischof S, Budimir A, et al. Antimicrobial PLA films from environment friendly additives. Composites Part B: Engineering. 2016; 102: 94-99. doi: 10.1016/j.compositesb.2016.07.017

[16]Chen CH, Yao YY, Tang HC, et al. Long-term antibacterial performances of biodegradable polylactic acid materials with direct absorption of antibiotic agents. RSC Advances. 2018; 8(29): 16223-16231. doi: 10.1039/c8ra00504d

[17]Popelka A, Abdulkareem A, Mahmoud AA, et al. Antimicrobial modification of PLA scaffolds with ascorbic and fumaric acids via plasma treatment. Surface and Coatings Technology. 2020; 400: 126216. doi: 10.1016/j.surfcoat.2020.126216

[18]Rodríguez-Contreras A, Torres D, Rafik B, et al. Bioactivity and antibacterial properties of calcium- and silver-doped coatings on 3D printed titanium scaffolds. Surface and Coatings Technology. 2021; 421: 127476. doi: 10.1016/j.surfcoat.2021.127476

[19]Anthierens T, Billiet L, Devlieghere F, et al. Poly (butylene adipate) functionalized with quaternary phosphonium groups as potential antimicrobial packaging material. Innovative Food Science & Emerging Technologies. 2012; 15: 81-85. doi: 10.1016/j.ifset.2012.02.010

[20]Tan L, Maji S, Mattheis C, et al. Antimicrobial Hydantoin‐grafted Poly(ε‐caprolactone) by Ring‐opening Polymerization and Click Chemistry. Macromolecular Bioscience. 2012; 12(12): 1721-1730. doi: 10.1002/mabi.201200238

[21]El Habnouni S, Lavigne JP, Darcos V, et al. Toward potent antibiofilm degradable medical devices: A generic method for the antibacterial surface modification of polylactide. Acta Biomaterialia. 2013; 9(8): 7709-7718. doi: 10.1016/j.actbio.2013.04.018

[22]Uner A, Doganci E, Tasdelen MA. Non‐covalent interactions of pyrene end‐labeled star poly(ɛ‐caprolactone)s with fullerene. Journal of Applied Polymer Science. 2018; 135(29). doi: 10.1002/app.46520

[23]He W, Zhang Y, Li J, et al. A Novel Surface Structure Consisting of Contact-active Antibacterial Upper-layer and Antifouling Sub-layer Derived from Gemini Quaternary Ammonium Salt Polyurethanes. Scientific Reports. 2016; 6(1). doi: 10.1038/srep32140

[24]Vidakis N, Petousis M, Velidakis E, et al. Three-Dimensional Printed Antimicrobial Objects of Polylactic Acid (PLA)-Silver Nanoparticle Nanocomposite Filaments Produced by an In-Situ Reduction Reactive Melt Mixing Process. Biomimetics. 2020; 5(3): 42. doi: 10.3390/biomimetics5030042

[25]Venkatesan J, Kim SK, Shim M. Antimicrobial, Antioxidant, and Anticancer Activities of Biosynthesized Silver Nanoparticles Using Marine Algae Ecklonia cava. Nanomaterials. 2016; 6(12): 235. doi: 10.3390/nano6120235

[26]Zhang Q, Zhai W, Cui L, et al. Physicochemical properties and antibacterial activity of polylactic acid/starch acetate films incorporated with chitosan and tea polyphenols. Polymer Bulletin. 2023; 80(12): 13319-13341. doi: 10.1007/s00289-023-04691-y

[27]Jeong SH, Hwang YH, Yi SC. Antibacterial properties of padded PP/PE nonwovens incorporating nano-sized silver colloids. Journal of Materials Science. 2005; 40(20): 5413-5418. doi: 10.1007/s10853-005-4340-2

[28]Perelshtein I, Applerot G, Perkas N, et al. Sonochemical coating of silver nanoparticles on textile fabrics (nylon, polyester and cotton) and their antibacterial activity. Nanotechnology. 2008; 19(24): 245705. doi: 10.1088/0957-4484/19/24/245705

[29]Saini S, Belgacem MN, Missoum K, et al. Natural active molecule chemical grafting on the surface of microfibrillated cellulose for fabrication of contact active antimicrobial surfaces. Industrial Crops and Products. 2015; 78: 82-90. doi: 10.1016/j.indcrop.2015.10.022

[30]Shi R, Geng H, Gong M, et al. Long-acting and broad-spectrum antimicrobial electrospun poly (ε-caprolactone)/gelatin micro/nanofibers for wound dressing. Journal of Colloid and Interface Science. 2018; 509: 275-284. doi: 10.1016/j.jcis.2017.08.092

[31]Saini S, Belgacem MN, Bras J. Effect of variable aminoalkyl chains on chemical grafting of cellulose nanofiber and their antimicrobial activity. Materials Science and Engineering: C. 2017; 75: 760-768. doi: 10.1016/j.msec.2017.02.062

[32]Muñoz-Bonilla A, Fernández-García M. The roadmap of antimicrobial polymeric materials in macromolecular nanotechnology. European Polymer Journal. 2015; 65: 46-62. doi: 10.1016/j.eurpolymj.2015.01.030

[33]Tian F, Decker EA, Goddard JM. Controlling lipid oxidation of food by active packaging technologies. Food & Function. 2013; 4(5): 669. doi: 10.1039/c3fo30360h

[34]Cuervo-Rodríguez R, Muñoz-Bonilla A, Araujo J, et al. Influence of side chain structure on the thermal and antimicrobial properties of cationic methacrylic polymers. European Polymer Journal. 2019; 117: 86-93. doi: 10.1016/j.eurpolymj.2019.05.008

[35]Dizman B, Elasri MO, Mathias LJ. Synthesis and antimicrobial activities of new water‐soluble bis‐quaternary ammonium methacrylate polymers. Journal of Applied Polymer Science. 2004; 94(2): 635-642. doi: 10.1002/app.20872

[36]Bruna JE, Quilodrán H, Guarda A, et al. Development of Antibacterial MtCU/PLA Nanocomposites by Casting Method for Potential Use in Food Packaging. Journal of the Chilean Chemical Society. 2015; 60(3): 3009-3014. doi: 10.4067/s0717-97072015000300007

[37]Gherasim O, Popescu RC, Grumezescu V, et al. MAPLE Coatings Embedded with Essential Oil-Conjugated Magnetite for Anti-Biofilm Applications. Materials. 2021; 14(7): 1612. doi: 10.3390/ma14071612

[38]Menon A, Durairajan R, Durai R, et al. Exploration of 3D Printing of Anti-Infective Urinary Catheters: Materials and Approaches to Combat Catheter-Associated Urinary Tract Infections (CAUTIs) - A Review. Critical Reviews™ in Therapeutic Drug Carrier Systems. 2022; 39(5): 51-82. doi: 10.1615/critrevtherdrugcarriersyst.2022040452

[39]Sandler N, Salmela I, Fallarero A, et al. Towards fabrication of 3D printed medical devices to prevent biofilm formation. International Journal of Pharmaceutics. 2014; 459(1-2): 62-64. doi: 10.1016/j.ijpharm.2013.11.001

[40]Wang Y, Jayan G, Patwardhan D, Phillips KS. Chapter: Antimicrobial and anti-biofilm medical devices: public health and regulatory science challenges. Antimicrobial coatings and modifications on medical devices; 2017.

[41]Shenzhen Esun Industrial Co., Ltd. Professional in 3D printing materials. Available online: https://www.esun3d.com/ (accessed on 7 February 2024).

[42]Aynali F, Doganci E, Doruk T, et al. Synthesis and characterization of antimicrobial polylactide via ring‐opening polymerization and click chemistry methods. Polymer International. 2018; 68(3): 385-393. doi: 10.1002/pi.5721

[43]Forster AM. Materials Testing Standards for Additive Manufacturing of Polymer Materials: State of the Art and Standards Applicability. National Institute of Standards and Technology; 2015. doi: 10.6028/nist.ir.8059

[44]Alharbi HF, Luqman M, Khan ST. Antibiofilm activity of synthesized electrospun core-shell nanofiber composites of PLA and PVA with silver nanoparticles. Materials Research Express. 2018; 5(9): 095001. doi: 10.1088/2053-1591/aad4df

[45]Liao Y, Xu Q, Zhang J, et al. Cellular response of chondrocytes to magnesium alloys for orthopedic applications. International Journal of Molecular Medicine. 2015; 36(1): 73-82. doi: 10.3892/ijmm.2015.2211

[46]Feoktistova M, Geserick P, Leverkus M. Crystal Violet Assay for Determining Viability of Cultured Cells. Cold Spring Harbor Protocols. 2016; 2016(4): pdb.prot087379. doi: 10.1101/pdb.prot087379

[47]Pop MA, Croitoru C, Bedo T, et al. Influence of Internal Innovative Architecture on the Mechanical Properties of 3D Polymer Printed Parts. Polymers. 2020; 12(5): 1129. doi: 10.3390/polym12051129

Copyright (c) 2025 Author(s)

This work is licensed under a Creative Commons Attribution 4.0 International License.