Fatigue damage model of neoprene rubber sandwiched with bi-directional carbon fabric

Abstract

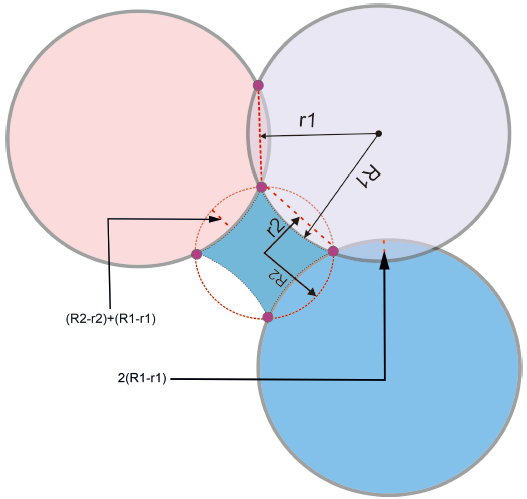

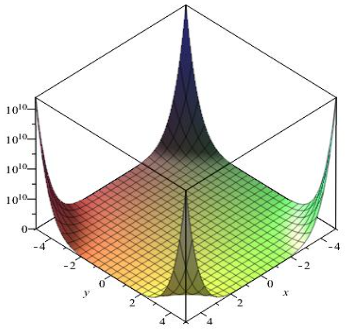

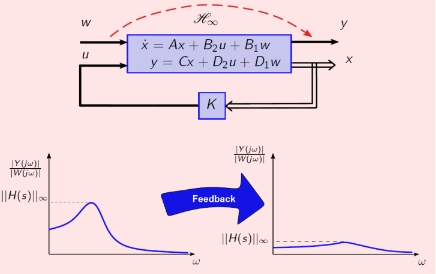

Fatigue is a phenomenon that occurs in materials when they are subjected to repetitive or cyclic loading, which can lead to the accumulation of damage over a time. The purpose of the present study is to develop a fatigue damage model incorporating experimental test results of axial tension and fatigue that utilizes the principles of continuum damage mechanics (CDM) to predict the damage accumulation in composite. Experimental testing in axial tensile tests involves dumbbell specimens of neoprene rubber sandwiched with bi-directional carbon fabric to constitute a composite material with the help of which material constants C10, C20, and C30 parameters are evaluated by the curve-fitting method. Fatigue tests were conducted for different displacements, from which constants s0 and S0 were figured out using a linear regression method. A mathematical model is developed, and MATLAB is used to relate stress and strain in Yeoh’s strain energy function to describe the nonlinear elastic behavior of elastomers incorporating material parameters evaluated by axial tensile tests and fatigue tests. The MATLAB script was run in ANSYS with this modified Yeoh hyperelastic model for evaluation of damage in composite and compared with damage evaluated by image processing software in scanning electron microscope (SEM) images for validation purposes.

References

[1]Le Cam JB, Huneau B, Verron E. Fatigue damage in carbon black filled natural rubber under uni- and multiaxial loading conditions. International Journal of Fatigue. 2013; 52: 82–94. doi: 10.1016/j.ijfatigue.2013.02.022

[2]Kang W, Liu J, Xiong W, et al. Basic mechanical and fatigue properties of rubber materials and components for railway vehicles: A literature survey. Reviews on Advanced Materials Science. 2022; 61(1): 587–610. doi: 10.1515/rams-2022-0054

[3]Suryatal B, Phakatkar H, Rajkumar K, et al. Fatigue Life Estimation of an Elastomeric Pad by ε-N Curve and FEA. Journal of Surface Engineered Materials and Advanced Technology. 2015; 05(02): 85–92. doi: 10.4236/jsemat.2015.52010

[4]Yeoh OH. Hyperelastic material models for finite element analysis of rubber. Journal of Natural Rubber Research. 1997; 12(3): 142–153.

[5]Ali A, Hosseini M, Sahari B. Continuum damage mechanics modeling for fatigue life of elastomeric materials. International Journal of Structural Integrity. 2010; 1(1): 63–72. doi: 10.1108/17579861011023801

[6]Zarrin-Ghalami T, Fatemi A. Cumulative fatigue damage and life prediction of elastomeric components. Fatigue & Fracture of Engineering Materials & Structures. 2012; 36(3): 270–279. doi: 10.1111/j.1460-2695.2012.01720.x

[7]Tang CY, Lee WB. Damage mechanics applied to elastic properties of polymers. Engineering Fracture Mechanics. 1995; 52(4): 717–729. doi: 10.1016/0013-7944(94)00333-D

[8]Mars WV, Fatemi A. A literature survey on fatigue analysis approaches for rubber, International Journal of Fatigue. 2002; 24(9): 949–961. doi: 10.1016/S0142-1123(02)00008-7

[9]Barbero EJ, Shahbazi M. Determination of material properties for ANSYS progressive damage analysis of laminated composites. Composite Structures. 2017; 176: 768–779. doi: 10.1016/j.compstruct.2017.05.074

[10]Shangguan WB. Study on the Effect of Different Damage Parameters on the Predicting Fatigue Life of Rubber Isolators. Journal of Mechanical Engineering. 2016; 52(2): 116-126. doi: 10.3901/jme.2016.02.116

[11]Shangguan WB, Wang XL, Deng JX, et al. Experiment and modeling of uniaxial tension fatigue performances for filled natural rubbers. Materials & Design. 2014; 58: 65–73. doi: 10.1016/j.matdes.2014.01.035

[12]Gehrmann O, Kröger NH, Muhr A. Displacement-controlled fatigue testing of rubber is not strain-controlled. International Journal of Fatigue. 2021; 145: 106083. doi: 10.1016/j.ijfatigue.2020.106083

[13]Luo RK. Rubber fatigue prediction for filled natural rubber under positive and negative R ratios. International Journal of Fatigue. 2022; 158: 106769. doi: 10.1016/j.ijfatigue.2022.106769

[14]Wang X, Shangguan W, Rakheja S, et al. A method to develop a unified fatigue life prediction model for filled natural rubbers under uniaxial loads. Fatigue & Fracture of Engineering Materials & Structures. 2014; 37(1): 50–61. doi: 10.1111/ffe.12081

[15]Li Q, Zhao J, Zhao B. Fatigue life prediction of a rubber mount based on test of material properties and finite element analysis. Engineering Failure Analysis. 2009; 16(7): 2304–2310. doi: 10.1016/j.engfailanal.2009.03.008

[16]Papadopoulos IC, Thomas AG, Busfield JJC. Rate transitions in the fatigue crack growth of elastomers. Journal of Applied Polymer Science. 2008; 109(3): 1900–1910. doi: 10.1002/app.28086

[17]Ayoub G, Naït-abdelaziz M, Zaïri F, et al. Multiaxial fatigue life prediction of rubber-like materials using the continuum damage mechanics approach. Procedia Engineering. 2010; 2(1): 985–993. doi: 10.1016/j.proeng.2010.03.107

[18]Wang B, Lu H, Kim GH. A damage model for the fatigue life of elastomeric materials. Mechanics of Materials. 2002; 34(8): 475-483. doi: 10.1016/S0167-6636(02)00175-8

[19]Lemaitre J. A Continuous Damage Mechanics Model for Ductile Fracture. Journal of Engineering Materials and Technology. 1985; 107(1): 83–89. doi: 10.1115/1.3225775

[20]Pamar JD, Naik BB, Latha OH, et al. Experimental Investigation of Bi Directional Carbon Fiber Composite. Materials Today: Proceedings. 2015; 2(4–5): 3008–3016. doi: 10.1016/j.matpr.2015.07.285

[21]ASTM, D3039/D3039M. Standard test method for tensile properties of polymer matrix composite materials. ASTM International. 2002.

[22]D412-98aASTM. Standard test methods for vulcanized rubber and thermoplastic elastomers. Annual Book of ASTM Standards; 2003.

[23]Saman F. Void content computation using optical microscopy for carbon fiber composites, Degree project in the field of technology materials design and engineering and the main field of study materials science and engineering. Stockholm Sweden; 2020.

Copyright (c) 2025 Author(s)

This work is licensed under a Creative Commons Attribution 4.0 International License.