Hydrothermally doping valve metal Nb into Titanate nanofibers structure for potentially engineering bone tissue

Abstract

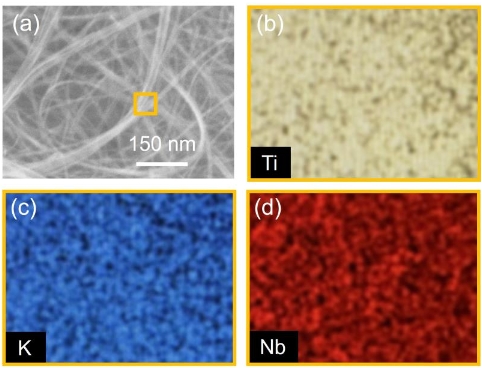

Recent research efforts in bone tissue engineering have been primarily directed towards manufacture-viable synthesis of biomaterials that can significantly enhance the biocompatibilities and osteogenic capabilities on the new biomaterials. This paper presents a straightforward, cost-effective, optimized, and well-controlled hydrothermal synthesis of Nb-doped potassium titanate nanofibers in high-purity. Characterization data revealed that the Nb-doping potassium titanate maintained the crystal structure, showing great promise for applications in bone tissue engineering.

References

[1]Zhang B, Li J, He L, et al. Bio-surface coated titanium scaffolds with cancellous bone-like biomimetic structure for enhanced bone tissue regeneration. Acta Biomaterialia. 2020; 114: 431-448. doi: 10.1016/j.actbio.2020.07.024

[2]Min Q, Liu J, Zhang Y, et al. Dual Network Hydrogels Incorporated with Bone Morphogenic Protein-7-Loaded Hyaluronic Acid Complex Nanoparticles for Inducing Chondrogenic Differentiation of Synovium-Derived Mesenchymal Stem Cells. Pharmaceutics. 2020; 12(7): 613. doi: 10.3390/pharmaceutics12070613

[3]Wu T, Li B, Wang W, et al. Strontium-substituted hydroxyapatite grown on graphene oxide nanosheet-reinforced chitosan scaffold to promote bone regeneration. Biomaterials Science. 2020; 8(16): 4603-4615. doi: 10.1039/d0bm00523a

[4]Oudadesse H, Najem S, Mosbahi S, et al. Development of hybrid scaffold: Bioactive glass nanoparticles/chitosan for tissue engineering applications. Journal of Biomedical Materials Research Part A. 2020; 109(5): 590-599. doi: 10.1002/jbm.a.37043

[5]Nie L, Deng Y, Li P, et al. Hydroxyethyl Chitosan-Reinforced Polyvinyl Alcohol/Biphasic Calcium Phosphate Hydrogels for Bone Regeneration. ACS Omega. 2020; 5(19): 10948-10957. doi: 10.1021/acsomega.0c00727

[6]Photo-crosslinked alginate nano-hydroxyapatite paste for bone tissue engineering - IOPscience. Available online: https://iopscience.iop.org/article/10.1088/1748-605X/ab9551/meta (accessed on 14 November 2023).

[7]Yang L, Gao C, Wei D, et al. Nanotechnology for treating osteoporotic vertebral fractures. International Journal of Nanomedicine. 2015; 5139. doi: 10.2147/ijn.s85037

[8]Venkataramana C, Botsa SM, Shyamala P, et al. Photocatalytic degradation of polyethylene plastics by NiAl2O4 spinels-synthesis and characterization. Chemosphere. 2021; 265: 129021. doi: 10.1016/j.chemosphere.2020.129021

[9]Saravanan S, Vimalraj S, Anuradha D. Chitosan based thermoresponsive hydrogel containing graphene oxide for bone tissue repair. Biomedicine & Pharmacotherapy. 2018; 107: 908-917. doi: 10.1016/j.biopha.2018.08.072

[10]Mohammadi M, Mousavi Shaegh SA, Alibolandi M, et al. Micro and nanotechnologies for bone regeneration: Recent advances and emerging designs. Journal of Controlled Release. 2018; 274: 35-55. doi: 10.1016/j.jconrel.2018.01.032

[11]Aldaadaa A, Al Qaysi M, Georgiou G, et al. Physical properties and biocompatibility effects of doping SiO2 and TiO2 into phosphate-based glass for bone tissue engineering. Journal of Biomaterials Applications. 2018; 33(2): 271-280. doi: 10.1177/0885328218788832

[12]Hashemi A, Ezati M, Mohammadnejad J, et al. Chitosan Coating of TiO2 Nanotube Arrays for Improved Metformin Release and Osteoblast Differentiation. International Journal of Nanomedicine. 2020; 15: 4471-4481. doi: 10.2147/ijn.s248927

[13]Liang F, Zhou L, Wang K. Apatite Formation on Porous Titanium by Alkali and Heat-Treatment. Surface and Coatings Technology. 2003; 165(2): 133-139. doi: 10.1016/S0257-8972(02)00735-1

[14]Marins NH, Lee BEJ, e Silva RM, et al. Niobium pentoxide and hydroxyapatite particle loaded electrospun polycaprolactone/gelatin membranes for bone tissue engineering. Colloids and Surfaces B: Biointerfaces. 2019; 182: 110386. doi: 10.1016/j.colsurfb.2019.110386

[15]Cadafalch Gazquez G, Chen H, Veldhuis SA, et al. Flexible Yttrium-Stabilized Zirconia Nanofibers Offer Bioactive Cues for Osteogenic Differentiation of Human Mesenchymal Stromal Cells. ACS Nano. 2016; 10(6): 5789-5799. doi: 10.1021/acsnano.5b08005

[16]Hwang C, Park S, Kang IG, et al. Tantalum-coated polylactic acid fibrous membranes for guided bone regeneration. Materials Science and Engineering: C. 2020; 115: 111112. doi: 10.1016/j.msec.2020.111112

[17]Zhang J, Huang D, Liu S, et al. Zirconia toughened hydroxyapatite biocomposite formed by a DLP 3D printing process for potential bone tissue engineering. Materials Science and Engineering: C. 2019; 105: 110054. doi: 10.1016/j.msec.2019.110054

[18]Dong W, Cogbill A, Zhang T, et al. Multifunctional, Catalytic Nanowire Membranes and the Membrane-Based 3D Devices. The Journal of Physical Chemistry B. 2006; 110(34): 16819-16822. doi: 10.1021/jp0637633

[19]Dong W, Zhang T, Epstein J, et al. Multifunctional Nanowire Bioscaffolds on Titanium. Chemistry of Materials. 2007; 19(18): 4454-4459. doi: 10.1021/cm070845a

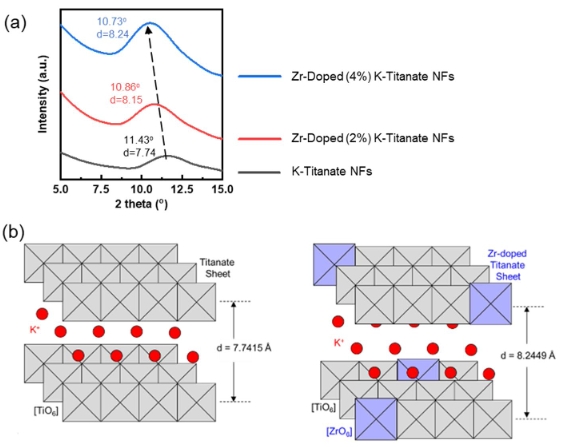

[20]Cole P, Tian Y, Thornburgh S, et al. Hydrothermal synthesis of valve metal Zr-doped titanate nanofibers for bone tissue engineering. Nano and Medical Materials. 2023; 3(2): 249. doi: 10.59400/nmm.v3i2.249

[21]Xiao Y, Tian Y, Zhan Y, Zhu J. Degradation of organic pollutants in flocculated liquid digestate using photocatalytic titanate nanofibers: Mechanism and response surface optimization. Frontiers of Agricultural Science and Engineering. 2023; 10(3), 492-502. doi: 10.15302/j-fase-2023503

[22]Yuan ZY, Zhang XB, Su BL. Moderate hydrothermal synthesis of potassium titanate nanowires. Applied Physics A. 2004; 78(7): 1063-1066. doi: 10.1007/s00339-003-2165-x

[23]Bi H, Zhu S, Liang Y, et al. Nb-Doped TiO2 with Outstanding Na/Mg-Ion Battery Performance. ACS Omega. 2023; 8(6): 5893-5900. doi: 10.1021/acsomega.2c07689

[24]Balbinot G de S, Bahlis EA da C, Visioli F, et al. Polybutylene-adipate-terephthalate and niobium-containing bioactive glasses composites: Development of barrier membranes with adjusted properties for guided bone regeneration. Materials Science and Engineering: C. 2021; 125: 112115. doi: 10.1016/j.msec.2021.112115

[25]Wang X, Liu SJ, Qi YM, et al. Behavior of potassium titanate whisker in simulated body fluid. Materials Letters. 2014; 135: 139-142. doi: 10.1016/j.matlet.2014.07.145

[26]Capanema N, Mansur A, Carvalho S, et al. Niobium-Doped Hydroxyapatite Bioceramics: Synthesis, Characterization and In Vitro Cytocompatibility. Materials. 2015; 8(7): 4191-4209. doi: 10.3390/ma8074191

Copyright (c) 2024 Yang Tian, Parker Cole, Yiting Xiao, Abdussamad Akhter, Trenton Collins, Lu Zhang, Yan Huang, Z. Ryan Tian

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors contributing to this journal agree to publish their articles under the Creative Commons Attribution 4.0 International License, allowing third parties to share their work (copy, distribute, transmit) and to adapt it for any purpose, even commercially, under the condition that the authors are given credit. With this license, authors hold the copyright.